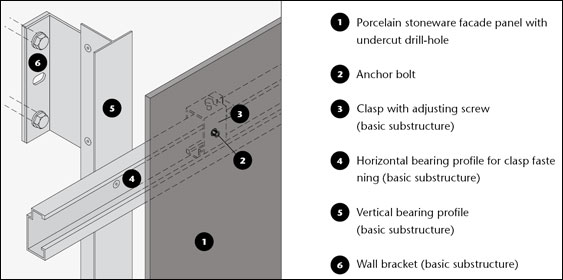

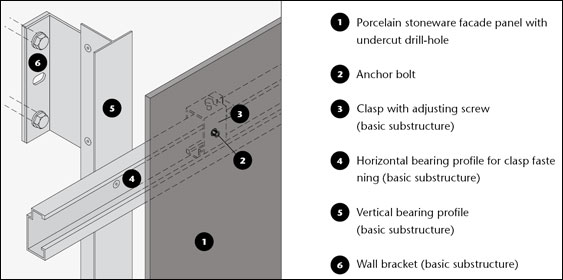

Porcelain stoneware facade panels with invisible fastening with undercut anchor

System description

On the reverse side of the porcelain stoneware panels, undercut anchors (anchor

bolts) are inserted in specially drilled undercut drill-holes as fastening points. At

least four fastening points per panel are required. The substructure parts (clasps)

are fixed in the anchors by means of stainless steel screws M6, and the porcelain

stoneware panels are hung in the substructure. Between the clasps and the ceramics,

elastic intermediate layers have to be installed. At all fastening systems

(basic substructures), constructional measures must be provided which durably

prevent a lateral movement of the panels. The fastening means, the substructure

and the execution must be in conformity with the specifications and conditions

stipulated in the European Technical Approval.

Keil undercut anchor KH for porcelain stoneware – facade panels, European

Technical Approval ETA-03/0055.

Porcelain stoneware with undercut anchor fastening

Essential system advantages

- No visible fastening means

- Fastening is possible with clasps or bearing profile

- The low panel weight of 23 kg/m² facilitates transport and handling and also permits the use in case of a statically demanding building structure

- Laying of the panels with straight joints or in bonds

- Formats of up to 45.5 x 90.5 cm

- Excellent look of the facade thanks to a particularly uniform joint structure

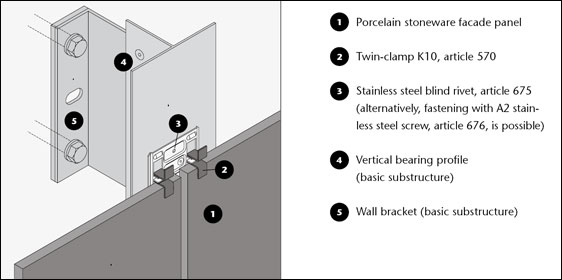

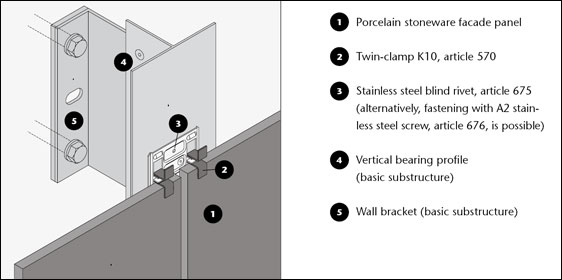

Porcelain stoneware facade panels with visible clamp fastening

System description

The porcelain stoneware facade panels are fixed on the substructure by means

of the stainless steel clamps K10. The colour of the clamp lips is matched to

the panel design. To prevent clattering and constraining forces in the case of

alternating wind loads, the facade panels are installed on the substructure in a

nonrigid way by means of foamed pieces.

Porcelain stoneware with clamp fastening K10

Essential system advantages

- Rapid and proven panel installation with well thought-out system components

- The low panel weight of 23 kg/m² facilitates transport and handling and also permits the use in case of a statically demanding building structure

- Suitable for use both on metal and wooden constructions

- Great design scope thanks to a wide variety of formats up to the size of 45.5 x 90.5 cm

Important:

The use of silicone caoutchoucs must be absolutely avoided, because silicone fluids segregate and effect sticky surfaces on which dirt adheres. Therefore,

please only use the system components mentioned (foamed pieces, EDPM rubber profile, neoprene rubber washer) and pointing, bonding and sealing

materials recommended by us. We will be pleased to inform you in detail. The usual final cleaning after completion of the construction works is still required.